The solid screening platform of Medicilon process department strictly complies with the registration regulations and regulatory requirements of China NMPA, FDA and other regulatory authorities, studies and controls the solid morphology of drug molecules in API and preparations, and can formulate the optimal screening strategy according to the material characteristics, including but not limited to crystallization method, solvent selection and ion selection.

The Importance of Solid Form Screening

The solid form screening of APIs is an important tool in the early process development of new drugs. The purpose is to find as many crystal forms as possible and determine the most suitable solid form for development, so that you can:

Improve the Quality of Drugs

There are significant physical and chemical differences between different polymorphs of the same drug (hygroscopicity, physical/chemical/mechanical stability, purity and impurities). This could lead to differences in solubility, dissolution rate and bioavailability, which directly affect the quality of the final product.

Optimize Intellectual Property

As a material structure patent, crystal form is an effective tool for prolonging the life cycle of new drugs. For generic drugs, it can break through the patent barriers of the original research and obtain the right to enter the market.

Compliance with Registration Regulations

The drug regulatory laws and regulations of China, US and other developed countries have set clear requirements for the content of crystal form research in new drug clinical trial applications, new drug marketing applications, and generic drug applications, and have formulated relevant guiding principles for crystal form research.

The solid form screening platform of Medicilon Process Department strictly complies with the registration regulations and regulatory requirements of China’s NMPA, the US FDA and other regulatory agencies. It conducts research and control on the solid form of drug molecules in APIs and preparations, and can formulate the best effect based on the characteristics of the substance screening strategies, including but not limited to crystallization methods, solvent selection, and ion selection.

Service Scope of Solid Form Screening Platform

Discovery

Various Salt Forms/Crystal Forms/Eutectic of API

Evaluation

The Druggability of Different Crystal Forms of API

Development

The API crystallization production process to obtain the target crystal form, morphology and particle size

Salt Screening

Purpose

Improve Drug Properties

Discover the Most Suitable Salt Type for Development

Ensure Effective Patent Protection

Avoid Prior Technology Patents

Technology

Free State Property Characterization

Solubility in Different Solvents

Choose the Right Counter Ion

Various Salt-Forming Technologies

Characterization of Physical and Chemical Properties

Solid and Solution Stability Research

Salt Type Selection and Recommendation

Patent Disclosure Materials

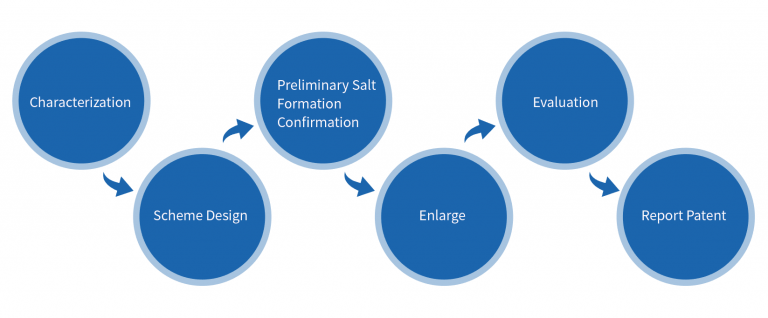

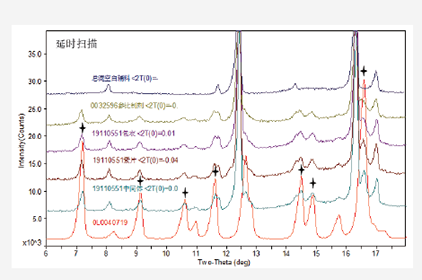

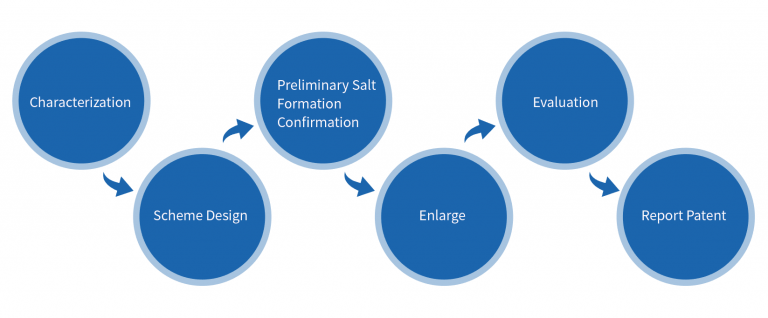

Salt Type Screening Process

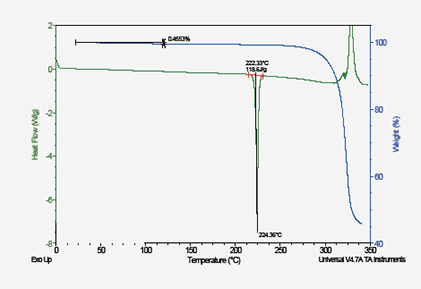

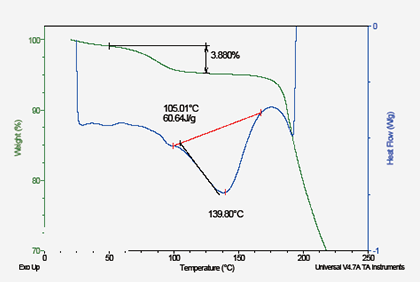

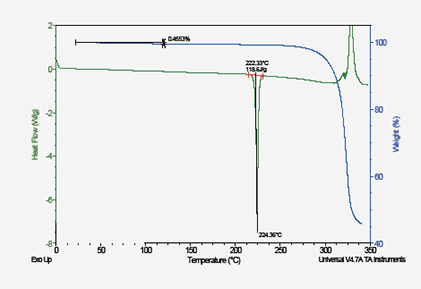

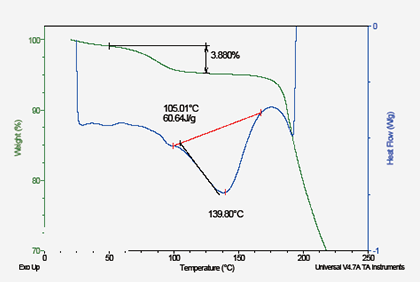

Thermal Analysis (TGA/DSC): Solvent (water) and Non-Solvate Analysis

No Crystal Type

Solvent (water) Compound

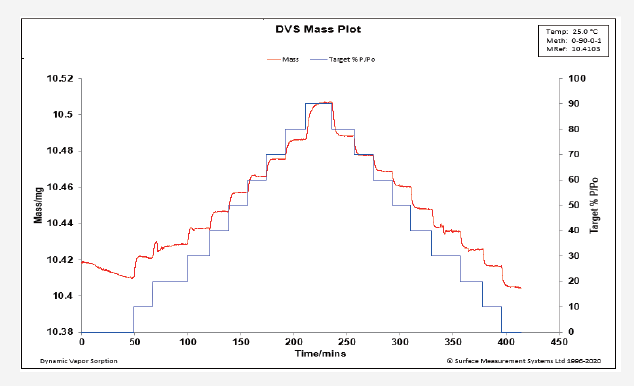

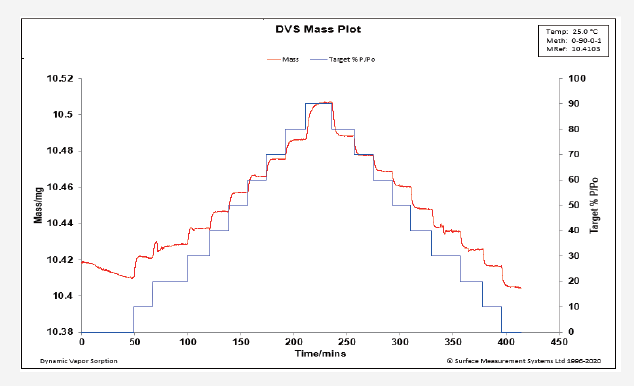

Dynamic Moisture Sorption (DVS) Applications – Inspection of Sample Moisture Absorption

Eutectic Screening

Purpose

Improve the Defects of the Free State Property

Discover the Most Suitable Eutectic Form for Development

Ensure Effective Patent Protection

Avoid Prior Technology Patents

Polymorph Screening

Purpose

Discover the Most Suitable Crystal Form for Development

Ensure Effective Patent Protection

Avoid Prior Technology Patents

Technology

Analysis of Existing Technologies

Multiple Crystallization Techniques

Characterization of Physical and Chemical Properties

Solid and Solution Stability

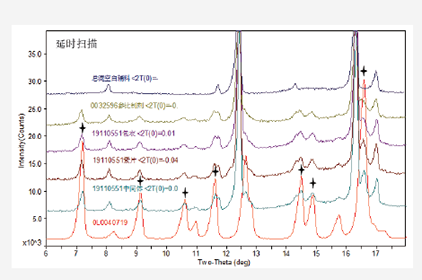

Analysis of the Relative Stability of Polymorphs

Crystal Type Selection and Recommendation

Patent Disclosure Materials

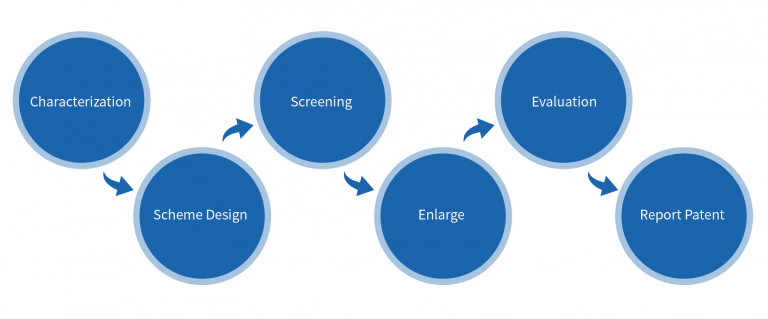

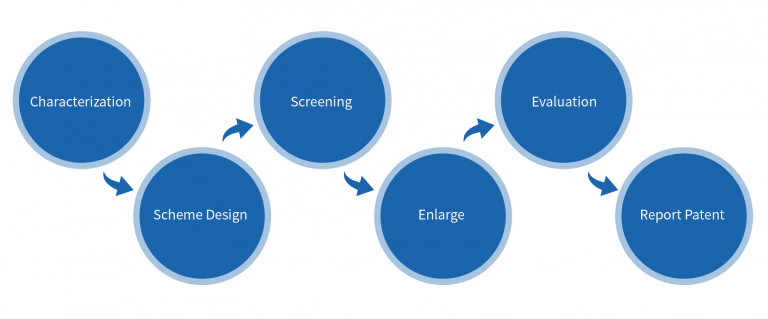

Polymorph Screening Process

Characterization→Scheme Design→Screening→Enlarge→Evaluation→Report Patent

Development and Verification of Qualitative, Quantitative and Limit Analysis Methods

Raw Material Crystallinity or Impurity Crystal Type Analysis

Qualitative and Quantitative Analysis of Crystal Forms of Raw Materials in Preparations

Development and Verification of Particle Size Distribution Analysis Method

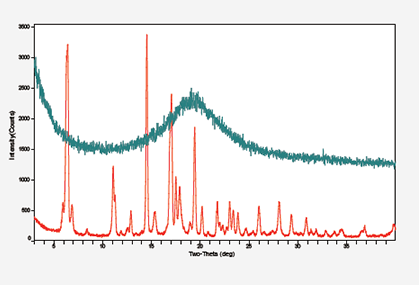

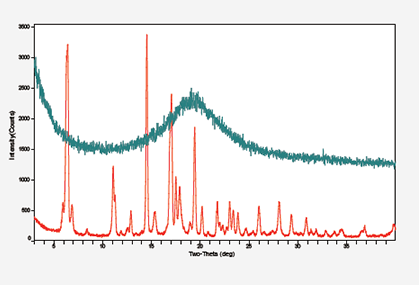

X-Ray Powder Diffraction Method (XRPD)

Crystallinity Check

Qualitative Analysis of Crystal Forms of Raw Materials in Preparations

관련 실험실

관련 실험실

관련 실험실

관련 실험실